AFFILIATED COMPANIES

INDORAMA ELEME PETROCHEMICALS LIMITED

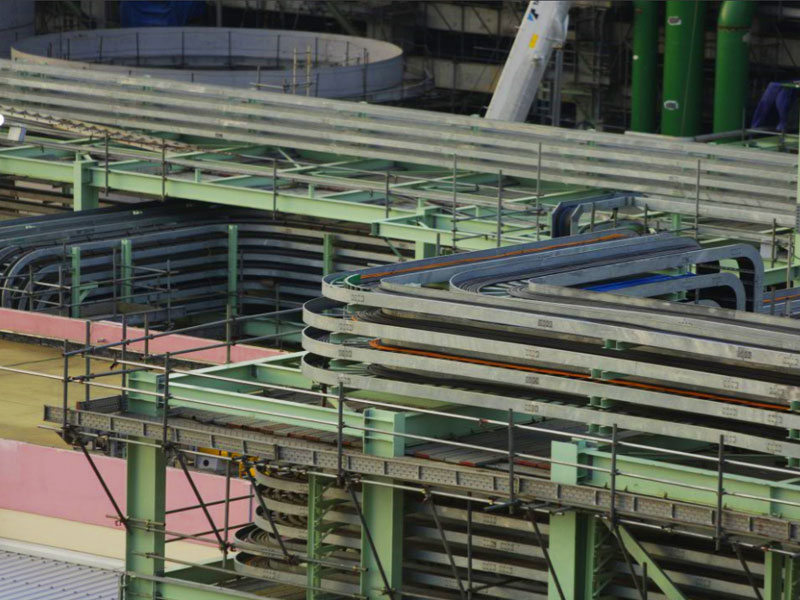

NigeriaIndorama Eleme Petrochemicals Limited (IPL) is the largest producer of olefins and polyolefin plastics in West Africa. Furthermore, it is the only producer of polyolefins in Nigeria and plays a vital role in sustaining the domestic downstream plastics industry. The petrochemical complex sits on a large industrial estate of over 300 hectares that also consists of a captive power plant, utilities, warehouses, and storage tanks. The complex consists of a mixed feed ethylene cracker plant, polyethylene plant producing HDPE and LLDPE, and a polypropylene plant. The main feedstock is Natural Gas Liquids (NGL) which is supplied by pipeline from a gas separation plant and is supplemented by Propylene Rich Feed (PRF) from nearby refinery. IPL produces over 300,000 tons of PE and PP resins annually, majority of which are sold in the domestic market.

INDORAMA ELEME PETROCHEMICALS LIMITED

Nigeria| Production Capacity Polyethylene Polypropylene |

320 KTA 120 KTA |

| Key Raw Materials | Natural Gas Liquids |

| # of Employees | c. 700 |

| Year Started | 1988 |

| Year Acquired | 2006 |

| Subsidiaries | Indorama Eleme and Fertilizer Chemicals Ltd (Nigeria) |

INDORAMA ELEME PETROCHEMICALS LIMITED

NigeriaOlefins

IPL’s Olefins Plant employs KBR’s Millisecond Cracking Furnace Technology. The NGL feed is cracked at high temperatures in the furnaces to produce ethylene, propylene and byproducts including hydrogen, methane, and gasoline. The cracked gases from the furnaces are cooled, compressed, combined with PRF feed, dried, and sent to the downstream purification section. The purification section employs a series of distillation and hydrogenation processes to produce polymer grade Ethylene and Propylene for the downstream PE and PP plants. The byproducts are internally consumed or marketed to domestic and international customers.

Polyethylene

The Polyethylene Plant is based on the SCLAIRTECH multi-reactor solution phase swing technology from Nova Chemicals. Ethylene from the olefins plant is dissolved in cyclohexane and polymerized in tubular and continuous stirred reactor in the presence of catalyst to produce low as well as high density grades of polyethylene with densityranging between 0.918 to 960 gm/cc and Melt Index of 0.20 to 100 g/10 min. The polymer is separated from the cyclohexane solvent, melted, and then extruded to form polyethylene pellets which are bagged and sold to consumers.

Polypropylene

The Polypropylene Plant is based on the Spheripol process technology of LyondellBasell. Liquid propylene, received from the olefins plant, undergoes polymerization reaction in loop reactors using a proprietary catalyst to form solid polypropylene in the reactors. The polypropylene is evacuated from the reactors continuously and separated into propylene monomer and polymer fractions in the downstream degassing sections. The polypropylene polymer is conveyed to the extrusion section where the polymer beads are converted into pellets and transported to storage for bagging and dispatch to customers.

Please click here to view the process flowchart.