AFFILIATED COMPANIES

Indorama India Private Limited (Fertilizer Division)

India

Indorama India Private Limited (Fertilizer Division) produces phosphate-based fertilizers in Haldia, which is located in the state of West Bengal in India. Its first Di-Ammonium Phosphate (DAP) plant was set up in 1985 and subsequently a complex fertilizer line was installed to produce DAP and NPK fertilizers, along with a plant to produce SSP fertilizers. Sulphuric acid is also manufactured at Haldia which is sold in the merchant market. The site has a production capacity of 1800 TPD of DAP, 3000 TPD of NPK, or a combination of the two as per the domestic market’s requirement. The SSP production capacity is 600 TPD.

Indorama India fertilizer business is conducted under the umbrella brand of Paras, which is a premier brand in Eastern India. Paras has a very strong brand equity supported by its unique specifications, quality, and customer support.

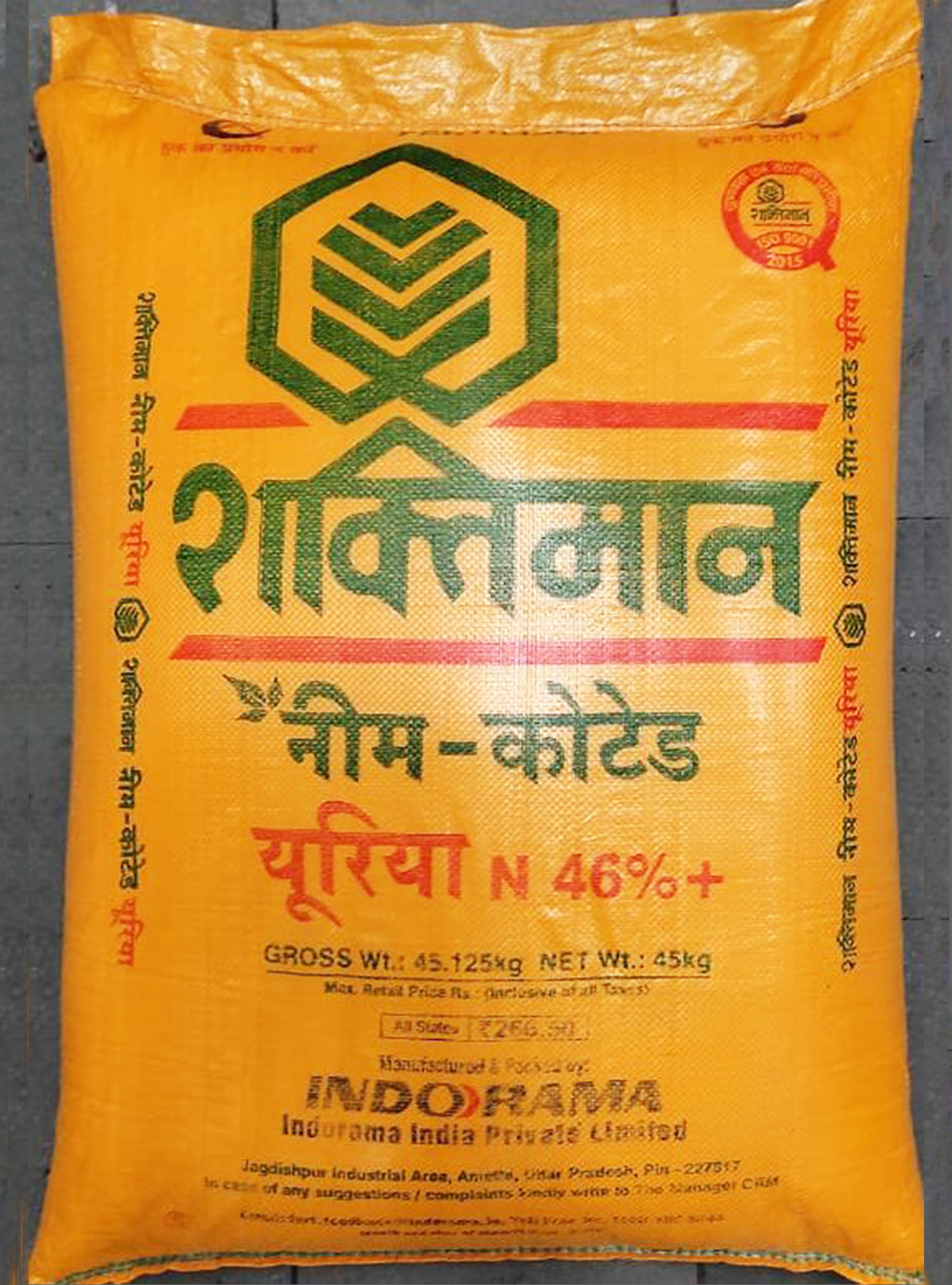

Indorama India Private Limited (“IIPL”), is also engaged in manufacturing, trading, and sale of urea and other agri-inputs at its facility in Jagdishpur, Uttar Pradesh in India. The facility has a state of art manufacturing plant with capacity to produce 1.2 mil tons of Urea per annum under its strong “Shaktiman” brand in Northern and Eastern India

With the aim of providing complete solutions, from “seed to harvest”, the “Shaktiman" brand of Urea is the farmers' preferred choice in the Indo-Gangetic plain.

The facility manufactures and markets Urea (Neem Coated), CFG (Customized Fertilizer Grade), and SHP (Soil Health Products). It also markets seeds, crop protection products, and plant health products (PHP) as part of its Purak business. With a sharp focus on farmers by providing total agri-solutions through a vast range of agri-input and technical know-how from seed to harvest accompanied with its after sales service, the Shaktiman brand enjoys a leading position and top consumer recall.

The facility is operating a gas-based Urea manufacturing fertilizer complex which is one of the most energy-efficient plants world-wide. The manufacturing consists of almost over 80 tons per day of customised fertilizer plant to produce different grades of customized fertilizers (CFG) and soil health products (SHP), and a separate 20 ton per day plant to produce Oorja. This is the first fertilizer plant in India to register CDM (Clean Development Mechanism) project with the UNFCCC.

The facility has its manufacturing location at Jagdishpur adjacent to the National Highway (NH-56) connecting Lucknow - Varanasi and about 80 km away from Lucknow, capital city of the state of Uttar Pradesh, India.

The Jagdishpur plant is certified with ISO 9001:2015 for quality system, ISO 18001:2007 for occupational health and safety management system, ISO 14001:2015 for environment management system, and Recertification Cycle from June’2018, ISO 50001:2011 for energy management system.

Indorama India Private Limited (Fertilizer Division)

India

| Particulars | Haldia Facility | Jagdishpur Facility |

| Production Capacity | ||

| DAP/NPK | 600 KTA (DAP equivalent) | |

| SSP | 200 KTA | |

| Urea (Neem Coated) | 1,200 KTA | |

| CFG (Customized Fertilizer Grade) | 33 KTA | |

| Key Raw Materials | Phosphoric Acid, Sulphur, Rock Phosphate, Ammonia, Muriate of Potash (MOP) |

Natural gas |

| # of Employees | c. 300 | c. 760 |

| Year Started | 1975 | 1988 |

| Year Acquired | 2018 | 2022 |

Indorama India Private Limited (Fertilizer Division)

IndiaProcess Plants at the Haldia Phosphate Fertiliser facility

Sulphuric Acid Plant:

The Haldia Phosphate facility has two Sulphuric acid plants, named SAP-1 and SAP-2, with capacity of 450 TPD and 300 TPD respectively. The main raw material for production of Sulphuric Acid is Sulphur, which is imported in granular solid form or in molten condition. The process is called Double Contact Double Absorption (DCDA). The sulphur is burnt in presence of excess air to form Sulphur di-oxide, which is converted to Sulphur tri-oxide in presence of a catalyst. The Sulphur tri-oxide is then absorbed in towers with circulating acid to obtain 98.5% Sulphuric acid product. The process of conversion from Sulphur to Sulphur di-oxide and then to Sulphur tri-oxide is highly exothermic and as a result steam is produced from the process as by-product, which is used in generation of power and as process steam.

Click here to see process flow chart of Sulphuric Acid plant

Complex Phosphatic Fertilizer Plants (DAP/ NPK):

There are two complex Phosphate Fertilizer (CPF) plants, named CPF-1 and CPF-2. Both the plants have flexibility to produce Di-Ammonium Phosphate (DAP) as well as NPK products. The capacity of CPF-1 plant is 900 TPD of DAP and CPF-2 is 1650 TPD of NPK10. The raw materials for DAP production are ammonia and phosphoric acid, while for NPK are ammonia, phosphoric acid and murate of potash (MOP). The basic process is the reaction between anhydrous ammonia and phosphoric acid to form Mono-Ammonium Phosphate (MAP) and then Di-Ammonium Phosphate (DAP). The PN reactor and pipe reactor slurry which is a combination of these two salts (DAP and MAP) is sprayed on to a bed of recycled fines in the granulator. The granular mass is then dried in a rotary drum dryer. The dried product is then screened and the desired sized product is transferred to the packaging plant after cooling the granules in a Fluidised Bed Cooler (FBC). The oversized granules are pulverized and mixed with undersize material and then recycled back to the granulator. For NPK production, MOP is mixed in recycle stream and sent back to granulator.

Click here to see process flow chart of DAP/NPK plant

Single Super-Phosphate Plant (SSP):

he plant has capacity to produce 600 TPD of SSP fertilizer in powder form. The raw materials for production of SSP are rock phosphate and sulphuric acid. Rock phosphate is first ground and then mixed with 98.5% strong sulphuric acid.

Click here to see process flow chart of SSP plant

Process Plants at the Jagdishpur Fertilizer facility

Ammonia Plant

The Ammonia Plant is based on NG-Steam Reforming process designed by Haldor Topsoe. The plant uses natural gas as the primary feedstock and fuel. Natural gas is first de-sulphurized and then steam reformed. The process stream is further subjected to secondary reforming with air. After a series of further steps, synth-gas, with a specific molar ratio of hydrogen to nitrogen, is made. The same is subsequently synthesized into Ammonia with the help of a catalyst. Carbon dioxide is formed during the process, which is separated, compressed, and sent to the urea plant for use in the production of Urea.

Urea Plant

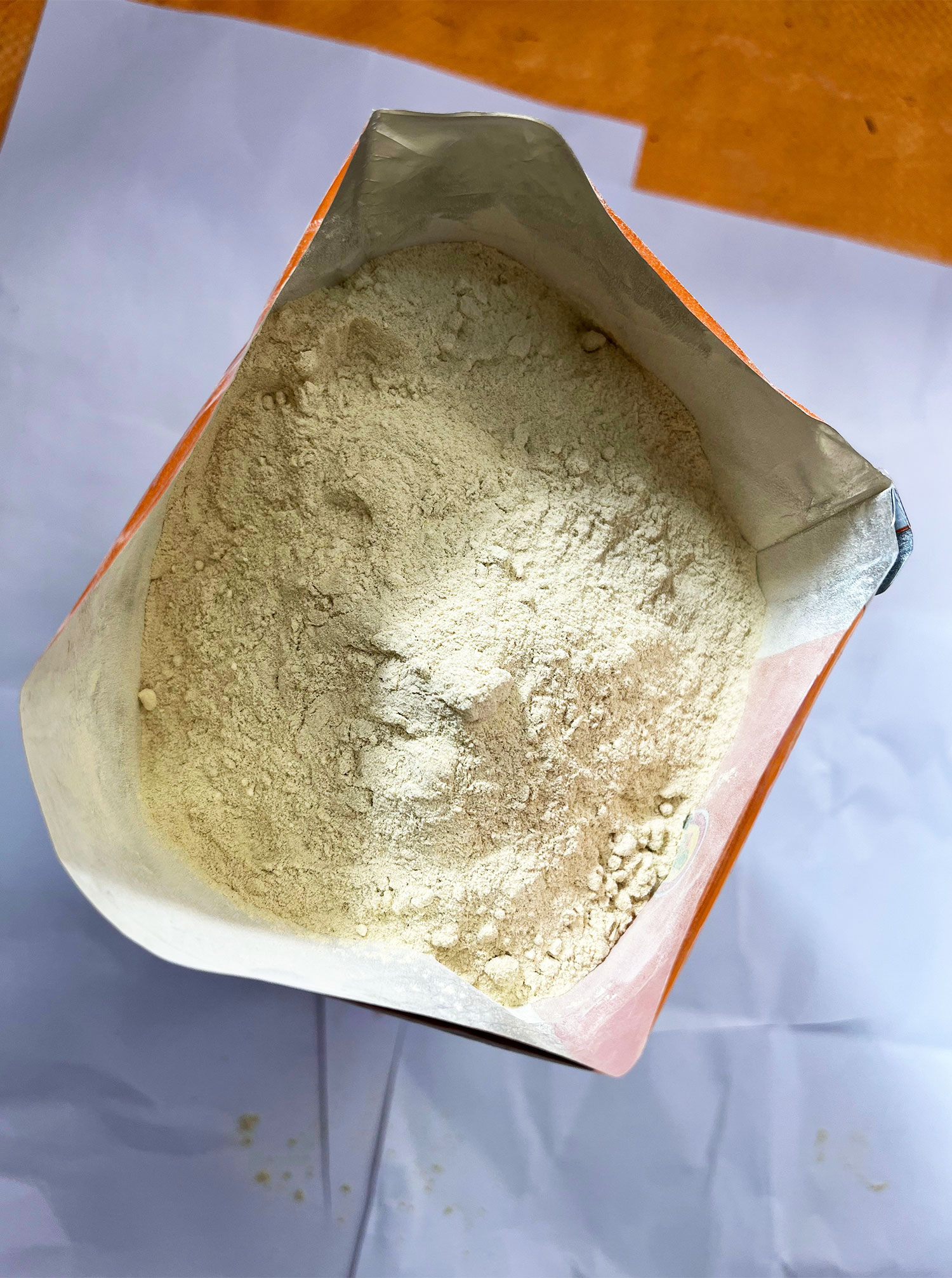

The Urea Synthesis process is based on Snamprogetti (SAIPEM) Technology and Urea Prilling. Urea is made using Ammonia and CO2. Ammonia and CO2, both supplied from the Ammonia Plant, are fed to a reactor at high pressure and temperature where Urea is formed. The conversion is partial and the unconverted reactants in an intermediate form, as ammonium carbamate, are removed in downstream sections and recycled back to the reactor. The Urea solution is concentrated to 99.7% and then send to the Prilling Tower for Prilled Urea formation.

Click here to see Process Flow Diagram