AFFILIATED COMPANIES

Indorama India Private Limited (Spandex Division)

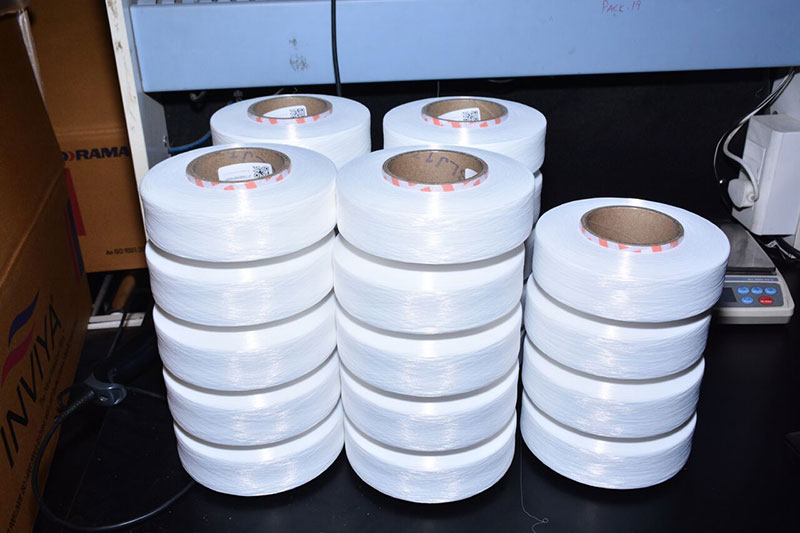

IndiaIndorama India Private Limited (IIPL) is the largest producer of spandex yarns in India. The plant was commissioned in 2012 with an annual production capacity of 5,000 tons. It is located in Baddi, Himachal Pradesh. The company's spandex yarn is marketed under the “INVIYA” brand. It’s sold primarily to domestic spun yarn producers, knitters, and texturizers in the Indian textile industry. The state of the art plant is equipped with the latest continuous polymerization technology and dry spun technology to produce spandex yarns. The principal raw materials, which are PTMEG and MDI, are imported from Asia. The company also has a continuous polymerization pilot plant to produce different polymer recipes as part of its product development activities. The current production capacity is close to 24,000 MT a year to meet the growing demands of the Indian textile industry.

Indorama India Private Limited (Spandex Division)

India| Production Capacity Spandex Yarns |

15 KTA |

| Key Raw Materials | PTMEG, MDI |

| # of Employees | c. 350 |

| Year Started | 2012 |

Indorama India Private Limited (Spandex Division)

IndiaSpandex is a lightweight, synthetic fiber that is used to make stretchable clothing and products. It is made up of a long chain polymer called polyurethane, which is produced by reacting a polygylcol with a diisocyanate. First produced in the early 1950s, spandex was initially developed as a replacement for rubber.

Spandex fibers are produced through a dry spinning process. The first step is production of the pre-polymer, which is made by mixing PTMEG and MDI. The compounds are mixed in a reaction vessel and under particular conditions they react to form a pre-polymer. The mixing ratio is strictly controlled to yield a polymer with very specific characteristics. The pre-polymer is subsequently reacted with amines. This is known as a chain extension reaction. The resulting solution is diluted with a solvent to produce the spinning solution. The solvent helps make the solution thinner and more easily to handle. It can then be pumped into the fiber production cell. In this cell, the polymer solution is forced through spinnerets. This causes the solution to turn into strands of liquid polymer. As the strands pass through the cell, they are heated in the presence of hot gas, thereby evaporating the solvent and making the yarn dry. Dry yarn after exiting the cell is passed through Air Twister and Spin Finish Oil applicator to give it desired surface characteristics before it is wound on the winding machine to form a spool.

Spandex yarns are used in many different type of textile applications such as warp knitting, circular knitting, core spun yarns, ply yarns, and covered yarns.

Please click here to view the process flowchart.