AFFILIATED COMPANIES

INDUSTRIES CHIMIQUES DU SENEGAL

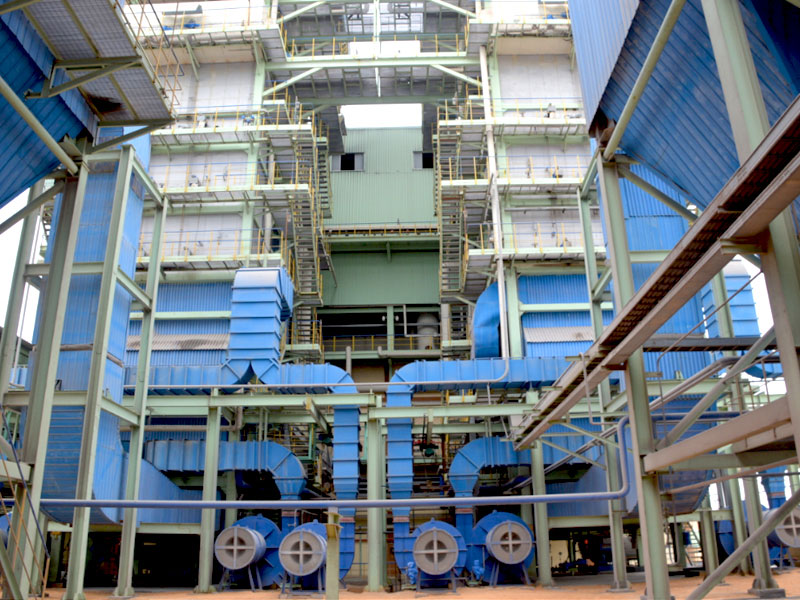

SenegalIndustries Chimiques du Senegal (ICS) is the largest producer of phosphate fertilizer products in Sub-Saharan Africa. Indorama acquired ICS in 2014. The company began mining of phosphate rock in 1960 and production of phosphoric acid in 1984. ICS is the largest industrial complex in Senegal and consists of three sites. The mine site is located 100 km from the capital of Dakar and has extensive reserves of high quality phosphate ore. The phosphoric acid plants are located in Darou and have a production capacity of 600,000 tons per year. The downstream fertilizer plant is located in Mbao, which is close to Dakar. The fertilizer plant can produce 250,000 tons per year of DAP and NPK products. ICS has well integrated logistics, including access to the railway system, its own fleet of locomotives and wagons, and dedicated berth at Dakar port. ICS exports the majority of its phosphoric acid to India, while it sells its fertilizer products in West Africa and international markets.

INDUSTRIES CHIMIQUES DU SENEGAL

Senegal| Production Capacity Phosphoric Acid Fertilizers |

600 KTA 250 KTA |

| Key Raw Materials | Sulphur |

| # of Employees | c. 1600 |

| Year Started | 1957 |

| Year Acquired | 2014 |

INDUSTRIES CHIMIQUES DU SENEGAL

SenegalSenegal has extensive reserves of high quality phosphate ore. The phosphate beds are part of a very extensive phosphate-bearing area in northeast of Dakar. The mineral is excavated by open cast method of mining. The overburden layer of sand and clay is divided into 3 benches and removed by different combination of machineries. Level 1 overburden is removed by bucket wheel excavators and conveyor system; Level 2 by shovel and dumpers; and Level 3 using draglines. After excavation, the phosphate rock is transported to the beneficiation plant

In the beneficiation plant, the mineral is screen in multiples stages using a variety of processes, including physical screens, scrubbers, rod mills, and cyclones. At the end, this yields phosphate minerals with very specific particle sizes which is best suited for further processing. In the floatation plant, the phosphate minerals are concentrated and later fed to the acid plant.

In the acid plant, concentrated phosphate rock is reacted with sulphuric acid to produce phosphoric acid. Sulphuric acid is first made by combusting sulphur, which yields sulphur dioxide; then converting sulphur dioxide to sulphur trioxide in the presence of a catalyst; and finally absorbing sulphur trioxide in water to form strong sulphric acid. The phosphate rock and a measured quantity of sulphuric acid is charged into reactors to form a slurry which is subsequently filtered in table vacuum filters to produce weak acid with 28% P2O5 concentration. The weak acid is sent to evaporators or concentrators to produce merchant grade phosphoric acid with 52% P2O5 concentration. Gypsum, which is a by-product of the process, is conveyed and stacked using advanced gypsum thrower equipment. Merchant grade phosphoric acid is transported by rail cars to the seaside for export or to the fertilizer plant to produce DAP or NPK blends.

ICS has a complex fertilizer manufacturing unit at Mbao, 18 km from Dakar. The manufacturing consists of several steps including granulation, drying, crushing, screening, cooling, coating, and storage. DAP is produced using ammonia and phosphoric acid, while various NPK blends are made using ammonia/urea, phosphoric acid, and potash.

Please click here to view the process flowchart.